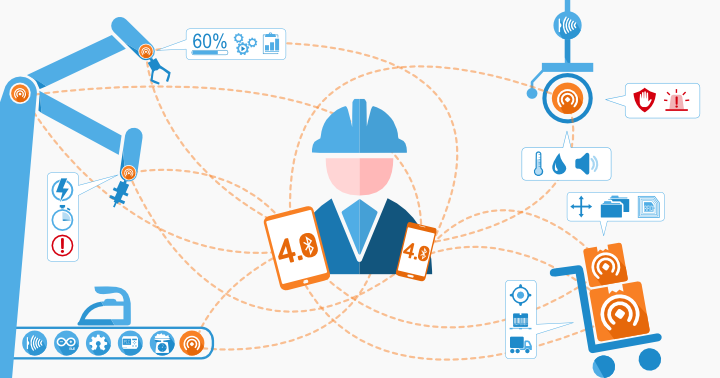

Why should you use the Bluetooth in the Industry 4.0?

Bluetooth Low Energy is one of key elements of IoT technologies (Internet of Things), and it's massively used to connect the mobile devices such as smartphones and tablets with everyday accessories such as headsets, smartwatch, fitness tracker, smartband…

On the contrary its use in manufacturing and working environment is very limited: what could be the benefits of using this technology in manufacturing companies?

Usually the Bluetooth, like its new version Low Energy commercially known as Bluetooth Smart or Bluetooth 4.0, works on frequency 2.4 GHz of the ISM band (Industrial, Scientific and Medical band). This frequency is free of any license of use and it's widespread worldwide.

Bluetooth Low Energy or BLE is designed for the world of wireless sensors and it has the following features:

- optimization of the transfer process of small data packages with extremely low energy consumption (approximately 0.01 mW);

- added security during the data transfer through recognition procedures between devices and encrypting of data transmitted;

- ability to set specific roles for the devices involved;

- possible transfers even for long distances (up to several kilometers).

In manufacturing environment to resort to using Bluetooth Low Energy sensors can be considered as an efficient alternative to the installation of wired networks. In fact wireless technology allows to place sensors and actuators even in areas of the factory that are difficult to reach with cables.

In the era of Industry 4.0, where machines must be able to communicate with each other and transmit data acquired by the sensors it becomes extremely important to ensure effective, reliable and secure communication between devices.

To employ technologies with extremely low power consumption, such as BLE, allows to introduce the use of Beacon, small wireless transmitters, in manufacturing environment and to implement a monitoring system in real time 24/7 really effective.

Our MES platform, jpiano®, is able to capture data from wirelss BLE devices and to support the development of tailored solutions for different manufacturing industry:

- production monitoring, transmission data collected by BLE wireless sensors about the progress of production (quantity, time, speed, realized items...) and the machine operation (energy consumption, operating temperature, machine state…) by reporting promptly any breakdowns or stops;

- tracking and identification of corporate resources, usage of Beacon (which are compatible with BLE protocols and act as active RFID tags) to send notifications on your location;

- monitoring the state of progress of a production line, placement of a Beacon on the being worked item to associate, on the basis of its location along the production line, the correct state of progress;

- recording movements inside the plants, interception of the location changes of products with Beacon and registration on our platform of these movements;

- safety and environmental monitoring, transmission of information about temperature, humidity, noise level, emissions of toxic substances or other environmental parameters by appropriate BLE wireless sensors. In this way the system is able to report any criticality and controls the healthiness of the working environment and safety;

- monitoring, detecting authorized or not people passage, and automatic generation of any subsequent notification by appropriate wireless BLE devices.