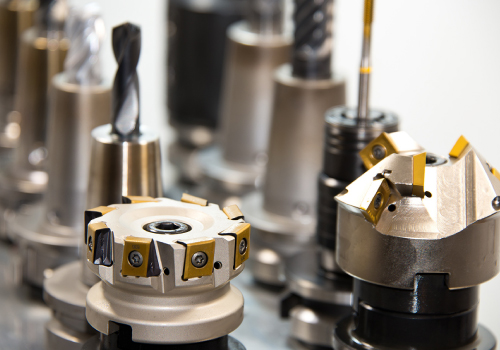

The tool shop is a fundamental department in every manufacturing company. Its correct management is essential to guarantee production efficiency and reduce costs.

Tools and molds are components subject to wear and tear, and inefficient management of these can lead to various problems, including:

- Unplanned downtime: Failure to maintain or replace tools and molds can lead to plant inefficiencies and production downtime.

- Production waste: Worn tools and molds can cause scrap production, resulting in increased costs.

- Increased maintenance costs: Frequent replacement of tools and molds can lead to an increase of maintenance costs.

Jpiano® MES Software

Jpiano® is an MES (Manufacturing Execution System) software that allows you to efficiently manage your tooling.

Jpiano® constantly monitors the wear and tear of tools and molds, detecting when intervention is needed. In this way, it is possible to reduce the risk of unplanned downtime, production waste, and increased maintenance costs.

- Real-time monitoring of wear and tear: Jpiano® collects and analyzes data from sensors on board the machine, allowing real-time monitoring of the wear and tear of tools and molds.

- Notifications of intervention needs: Jpiano® alerts the operator when it is necessary to intervene to replace a worn tool or mold.

- Tool and mold warehouse management: Jpiano® allows you to efficiently manage the tool and mold warehouse, avoiding excessive purchases that create obsolescence.

Learn more about Jpiano® on the dedicated page:

Contact us to learn more

We are here to answer all your questions and doubts.

Choose AEC Soluzioni as your partner for digitalization

We can help you to:

- Improve production efficiency in all phases of the production cycle, from order management to process monitoring to logistics.

- Reduce production, maintenance, and warehouse costs.

- Avoid unexpected downtime, improving product quality and customer satisfaction.