4.0 Interconnection

of machinery and plants

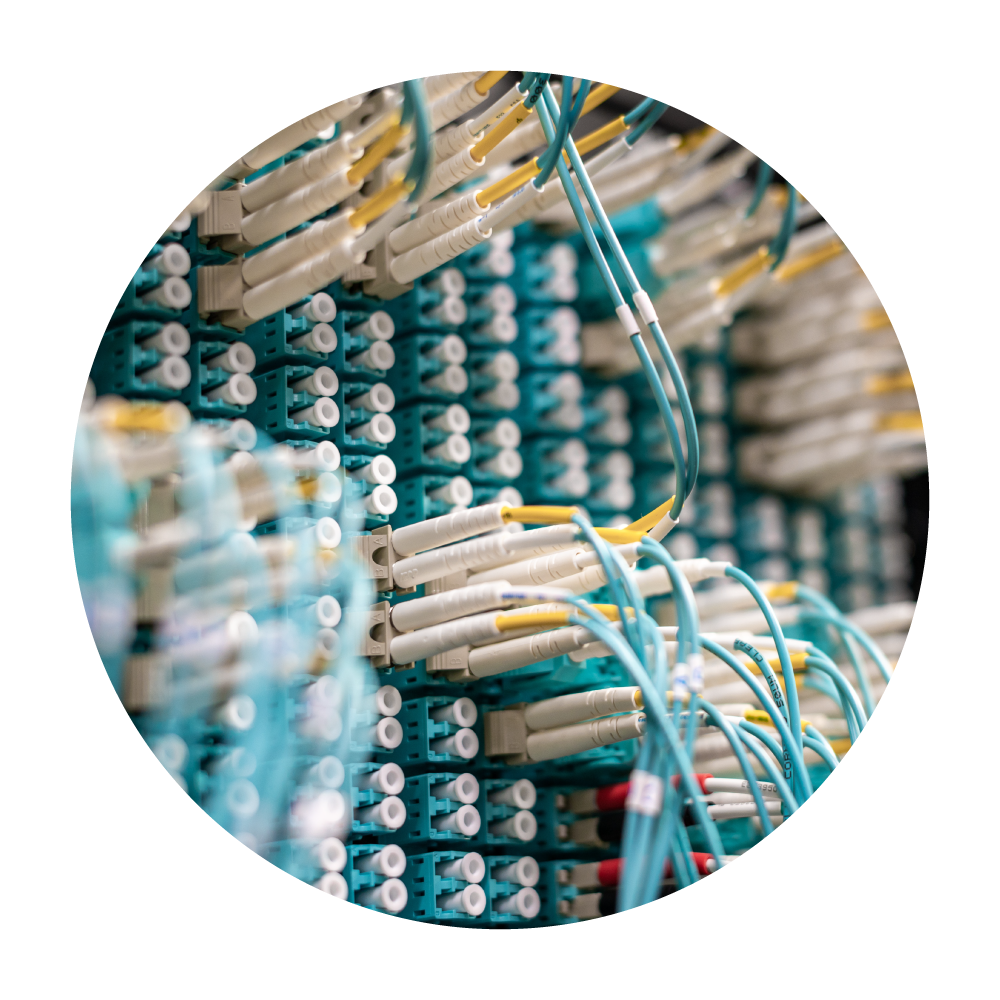

As simple as plugging it in

The connection of machinery and plants is the first step in creating a 4.0 ecosystem with all the resulting advantages.

Technological development has helped to simplify an intervention that could have been complicated and burdensome twenty years ago. Today we’re able to communicate with all the main technologies present in the production plants. It’s not necessary to have state-of-the-art systems to enjoy the efficiency of a smart factory.

Benefits of interconnection 4.0

-

Acquire production, status, process and tool wear data

-

Monitor the performance and plant status on smartphones, smartwatches and tablets, by receiving notifications about blocks and alarms

-

Set in real-time the recipe on the machine with the necessary settings for its operation

-

Plan the next activities of the machine taking into account its real availability

-

Keep under control environmental parameters (humidity, air quality, etc.) and auxiliary systems (compressed air, scales, dryers, electrical panels, etc.)

Interconnection mode

If the machine is 4.0-ready, it implies that uses standard protocols (eg OPC-UA) that promote the intervention speed. In other cases, we have a wide variety of ready-to-use connectors. If it’s necessary to connect very specific machines, we’re able to develop ad hoc connectors.

Basically, we communicate with everything