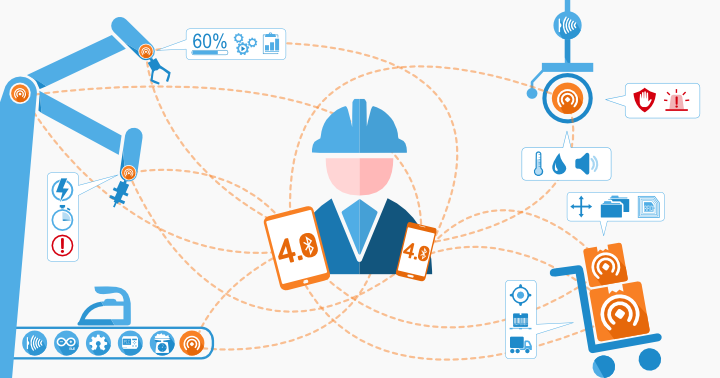

ID systems

Modern identification technologies respond to the need of automatic and real-time association of information about advances, business operators, materials and all the other variables that contribute to the production process. The adoption of these technologies minimizes the operation of the department resulting in an increase in production efficiency as speeds up the data acquisition while reducing the time, cost and errors ...!

In addition, these identification devices enable the company to manage transparently the entire production chain by providing a complete and efficient system of tracking and tracing.

The more established technologies in this area are:

Beacon devices

The beacons are small wireless transmitters with low power consumption that, if placed in a physical space as a selling point, a museum or an airport, they can signal their presence to a device (smartphone or tablet). This technology uses a Bluetooth Low Energy, BLE, o Bluetooth 4.0 to send information and geo-localized content to devices in the vicinity.

The user, by installing an application on your device Beacon-ready, can display:

- Distance, so you can easily locate the nearest beacon. The extension of the signal transmitted by a beacon varies depending on the position in which it is installed: elements such as walls, doors and other physical obstacles reduce the transmission range. In optimal conditions, the transmission power is around 70 meters.

- Push notifications, visible on the display of your device when you are near a beacon. The user by activating this application may receive contextual information in real time.

Leveraging Bluetooth Low Energy, beacons are able to transmit microgeolocation data even indoors, where the classic GPS is ambiguous, and multimedia content easily updated and modified in real time.

RFID, Radio Frequency Identification

This technology is an advanced system for the radio frequency identification information related to materials, operators, semi-finished materials…

An RFID tag consists of a chip and an antenna assembled on small sized supports with different forms, colors and materials. The information is stored in the chip and communicated via the antenna, called transponder or tag, to the appropriate reader. There are different types of RFID tags:

- Passive, when the RFID tag is able to receive and transmit information only when it is within range of the reader. This type of tag is the most widespread on the market as it is the most economical solution. Nevertheless among its limits there are the reading distance (rather small) and incompatibility with applications of real-time location (RTLS).

- Active, when the RFID tag contains within it also a transceiver (such as the RFID reader). These tags can then be activated independently of the presence of a reader in the vicinity and the signal generated by them can reach reading distances also much higher than those passive. Additionally they are used for the realization of systems of real-time location (RTLS). Of course they are more expensive than passive RFID tags because they require more maintenance and attention during use.

- Semipassive, that passive RFID tags but with battery and therefore also called BAP, Battery Assisted Passive.These tags do not use the battery to generate the signal but to reduce the reading distance while keeping the chip in a state of stand-by.

Since there are thousands of RFID tag different application possibilities are endless: for example in the industrial sector may present as tags printed on thin plastic substrates such as adhesive labels, tickets or badge.

Tag NFC, Near Field Communication

This technology represents an evolution of the systems of contactless identification RFID. The NFC devices, unlike RFID systems, allowing a two-way short-range wireless communication. In this way the devices involved may send each other not only information but also media files.

Barcode

Barcode technologies are still the most widespread and consist of high-contrast graphics printed on adhesive labels or other media so they can be read by optical devices, the sensors scanned and decoded by special programs. In industry these codes are used to uniquely identify any type of business asset such as raw materials, equipment, machines, operators, products, pallet ... operators when they read a bar code may use optical wireless or connected via USB to a computer or, in the case of codes in line, resort to fixed stations scanning for automatic reading.

Magnetic badge or identification

These cards the size of a credit card and made of plastic material have a magnetic stripe containing a small amount of information, and are primarily used to identify the staff. The reading is made through swiping the card into a card reader equipped with a magnetic head that records as the times of input and output or the declarations of the operators at suitable locations.