FOOD INDUSTRY 4.0

A delicious combination

Nice to meet you, jpiano®

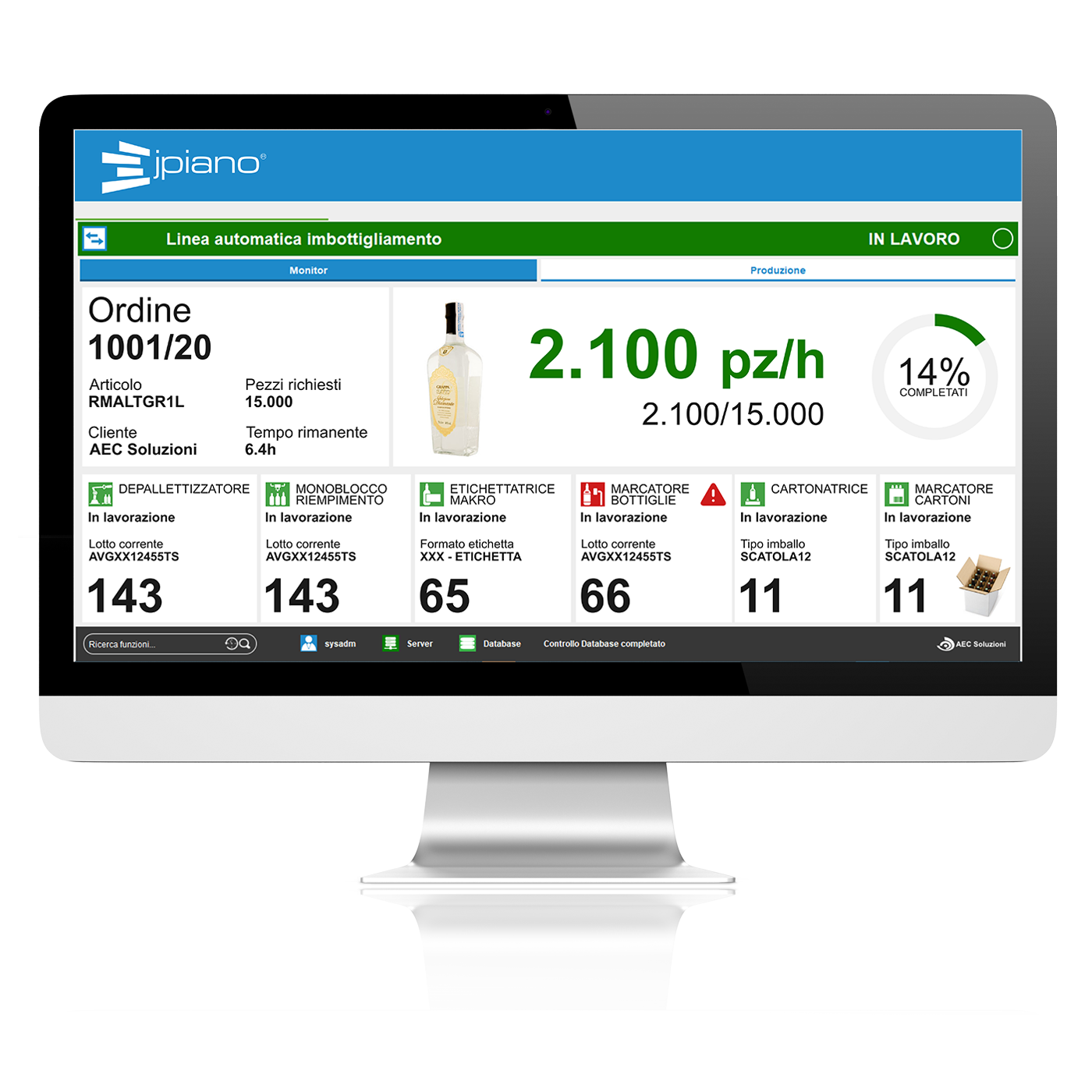

Jpiano® is an advanced software tool developed to measure to control and optimize every aspect of the production process. Its implementation in the Food and Beverage sector can respond to all the main typical problems of this type of production.

The important matters

EFFECTIVE PLANNING

CHECKING THE AVAILABILITY OF RESOURCES AND MATERIALS

QUALITY ASSURANCE

THE FACTORY WITHIN REACH OF TABLET

TRACEABILITY OF THE PRODUCTION CHAIN

CUSTOMER LOYALTY IMPROVEMENT

COSTS OPTIMIZATION

LOGISTICS MANAGEMENT

The digitalization advantages

Planning

Optimizing sequences and minimizing the number of starts in production, in terms of recipe change and format change, allows you to: reduce costs related to production stops for line setup and increase the saturation of the lines.

Resources

Raw materials and equipment are always available thanks to stock management and scheduling of requirement based on real needs.

Quality

Real-time monitoring guarantees greater product quality and uniformity and allows for a significant reduction in errors, rejects and waste.

Information

All production data are always available and easily accessible: machine status, resource availability, process progress, quality control, logistics, etc.

Traceability

The traceability of products is always ensured by registration of:

- supplier data

- links between materials, semi-finished and finished products

- information relating to production and logistics processes

Loyalty

Compliance with delivery times, greater process flexibility together with an increase in quality and more accurate supply chain traceability can improve customer loyalty.

Costs

Intelligent planning, timely notification of critical situations and an in-depth analysis of the data coming from the processes make it possible to activate improvement actions to reduce operating costs.

Logistics

All aspects of logistics under control. From the planning of shipments and carriers to the management of multi-material containers.